Litšobotsi tsa Bohlokoa:

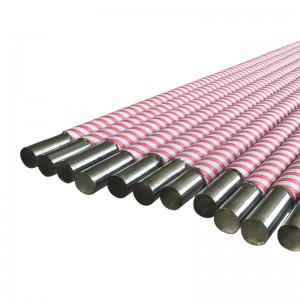

- Matla a phahameng a 1045 a ne a tloaetse ho otlolla matla a mangata a 1045 tšepe ena e ikhethang, e ipehele e loketseng likopo tse boima.

- Corrome e hatellang: Sebaka se hatellang se hlahang: se hlahang ho litsietsi tsa litlolo tse sirelelitsoeng khahlanong le baemeli ba sireletsehileng, ba etsa bonnete ba nako ea ho phela le maemong a thata le libakeng tse thata.

- Qete e boreleli ea boreleli: Lefatše le boreleli le fokotsa khohlano, fokotsa lilakane

Melemo:

- Ho hlomoha ho hopolofatsa: Ho hlakisa boiketlo ba matla a tšepe le crate ea crate ea crad e akaretsang likhetho tsa setso, litlhoko tsa tlhokomelo ea tlhokomelo le lintlafatso.

- Ts'ebetso e ntlafalitsoeng: Moriti o fokotsehileng mme o roetse ts'ebetso e matla, ho fetolela ts'ebetso e phahamisitsoeng le bophelo bo atolositsoeng.

- Lipehelo tsa "Hydraulic le litsamaiso tsa Hydraulic le tsa Pneumatic ho mochini oa litsoalle,1045 CHROME e nang le molamue hlahisa lits'ebetsong tse fapaneng.

Likopo:

- Fydraulic cylinser: molamu o tiisa motsamao o tšepahalang le o nepahetseng kahare ho Mokhanni oa Hydraulic, esita le tlas'a khatello e phahameng.

- Li-coneels tsa Pneumatic: Ho loketse lits'ebetso tsa Pneumatic, ho tšoarella ha molamu le likhohlano tse tlase li kenya letsoho ts'ebetsong ea matla le tšebeliso e telele.

- Mechine ea indasteri: Ho tloha litsamaiso tsa ho tsamaisa mechini, tšebeliso ea molamu e ntlafatsa ts'ebetso ea lisebelisoa tsa indasteri tse fapaneng tsa indasteri tse fapaneng.

Ts'ebetso ea Tlhahiso:

- Ho fetohela le ho pola: Ho nepahala ho fetola le ho betla lere la 1045 steel rod ho litekanyo le botle bo boreleli, li beha sethala sa likepe.

- Chrome plating: Litšoantšo tsa elektroplating li beha lela ea chromium sebakeng sa molamu, u fetisetsa ho hanela ho hanela ho loantšana le ho hanyetsa.

Ngola molaetsa oa hau mona 'me u e romelle ho rona