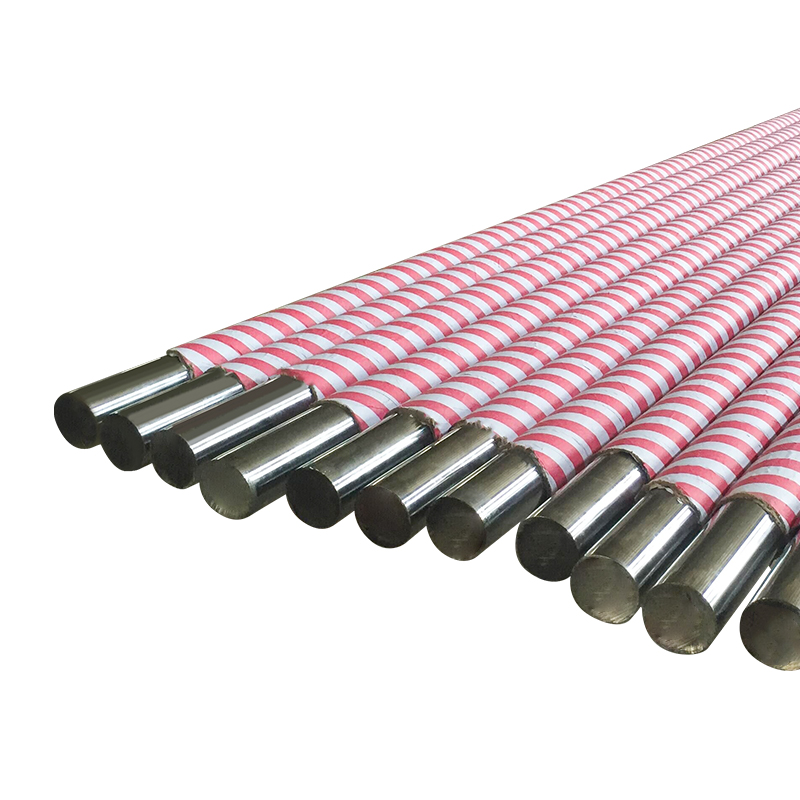

Kenyelletso ho lithupa tse thata tsa chrome

Lined tse thata tsa choted ke mekotla ea lejoe la li indasteri, e tsebahalang ka ho tšoarella ha eona le ho hanela ho roala le ho taboha. Li-masholu ana a sebelisoa indastering ea lintho tse fapaneng, ho tloha ho likoloi litsamaiso tsa Hydraulic, ka lebaka la khanya ea bona ea tlhaho le bophelo bo bolelele.

Mokhoa oa ho etsa lihlahisoa tsa li-strome tse thata

Ho isoa lithupelong tsena ho kenyelletsa letoto la mehato e rarahaneng. Ho qala ka khetho ea lintho tsa motheo, hangata tšepe, lere le ntse le hloekisa. Ka nako eo e ne e lejoe ke electroplating, moo mokato a chrome a kentsoeng holim'a eona.

Thepa ea lithupa tsa chrome tse thata

Matla ana a lithupa tse khahlang le ho hanyetsa litšusumetso tse peli, litšoaneleho tse peli li bohlokoa haholo litlhophiso tsa liindasteri. Tšenyo ea potoloho ea lithupa tsena ha e nke feela boipiletsong ba tsona bo botle empa hape e etsa karolo ea bohlokoa ts'ebetsong ea bona.

Likopo tsa lithupa tse thata tsa chrome tse halikiloeng indastering e fapaneng

Lefapheng la likoloi, lithupa tsena li bohlokoa molemong oa ho fokola ha motho a tsitsinyetsana a ho tšoha le likarolo tse ling. Indasteri ea kaho ea molao e ba hlalosetsa mochini o boima. Karolo ea bona ka litsamaiso tsa Hydraulic le ea fokotsang le tsona lia hlokomeleha, li fana ka ts'ehetso le katleho.

Ho bapisa li-chrome tse thata ka thata ka lithupa tse ling tsa indasteri

Ha li bapisoa le lithupa tse ling tsa indasteri, lirethe tse halikiloeng tse thata hangata li tsoa ka holimo mabapi le ho tšoarella le ts'ebetsong. Li boetse li theko e boima haholo ha nako e ntse e ea, leha e le matsete a phahameng a holimo.

Malebela a tlhokomelo bakeng sa lithupa tse thata tsa Chrome tse halikiloeng

Tlhokomelo e tloaelehileng ke senotlolo sa ho lelefatsa bophelo ba bona. Sena se kenyelletsa tlhahlobo ea tloaelo le ho sebetsana le matšoao a ho roala kapa driverane hanghang.

Tsoelo-pele ea theknoloji ea chome e thata

Tsoelo-pele ea morao-rao tšimong ena e tsepamisitse maikutlo ho ntlafatsa ts'ebetso ea ho tšoaea bakeng sa boleng bo botle le katleho. Mekhoa ea Bokamoso e Bontša mekhoa e metle haholoanyane ea tikoloho.

Liphephetso le tharollo ho chost plating

Ho bile le mathata a bophelo ba tikoloho a bile phephetso indastering ena. Leha ho le joalo, melao e mecha le mekhoa e sireleli e sirelelitsoeng hore e tlohele mathata ana.

Lithuto tsa linyeoe: ho kenella ka katleho ha lithupa tse thata tsa chrome tse thata

Liithuti tse 'maloa li totobatsa ts'ebeliso e atlehang ea melamu ena indastering e fapaneng. Mehlala ena ea lefatše ea lefatše e fana ka leseli la bohlokoa ka tsela ea bona le katleho.

U reketa tataiso bakeng sa lithupa tse thata tsa Chrome

Bakeng sa bareki ba nako ea pele, ho bohlokoa ho nahana ka lintlha tse kang boholo ba lipalesa, boholo ba chrome le kopo e reriloeng. Ho batla likeletso tsa botsebi ho ka ba molemo.

Malebela a ho kenya le mekhoa e metle

Ha ho kenya ho khothaletsoa ho khothaletsoa ho khothaletsoa, ho cheseha ho duya ho ka etsa mosebetsi ona ka mehato ena ea polokeho le litataiso.

Likhetho tsa tumellano ea li-chrome li-rods tse thata

Likhetho tsa tloaelo li ngata haholo, li lumella bareki ho tsamaisa mathe masimong ana ho litlhoko tse ikhethang tsa indasteri.

Likarolo tsa molao le tsa taolo

Ho latela maemo a machabeng le melaoana ha a bohlokoa bakeng sa ho latela le polokeho.

Bokamoso ba lithupa tse thata tsa Chrome

Indasteri e etselitsoe kholo ea kholo le ho nts'etsopele le tsoelo-pele ea theknoloji.

Li-chome tse thata tse halikiloengke ntho ea bohlokoa indang ea sejoale-joale, e nyehelang matla a mangata, ho hloka botsitso le ho se sebetse. Mekhoa ea bona e mengata ea likopo le tsoelo-pele ea Mahlomola a Mahlomola a sebetsang a ba khetholla khetho e tšepahalang ho bakhahlelo ba bangata.

Nako ea ho romella: Dec-05-2023