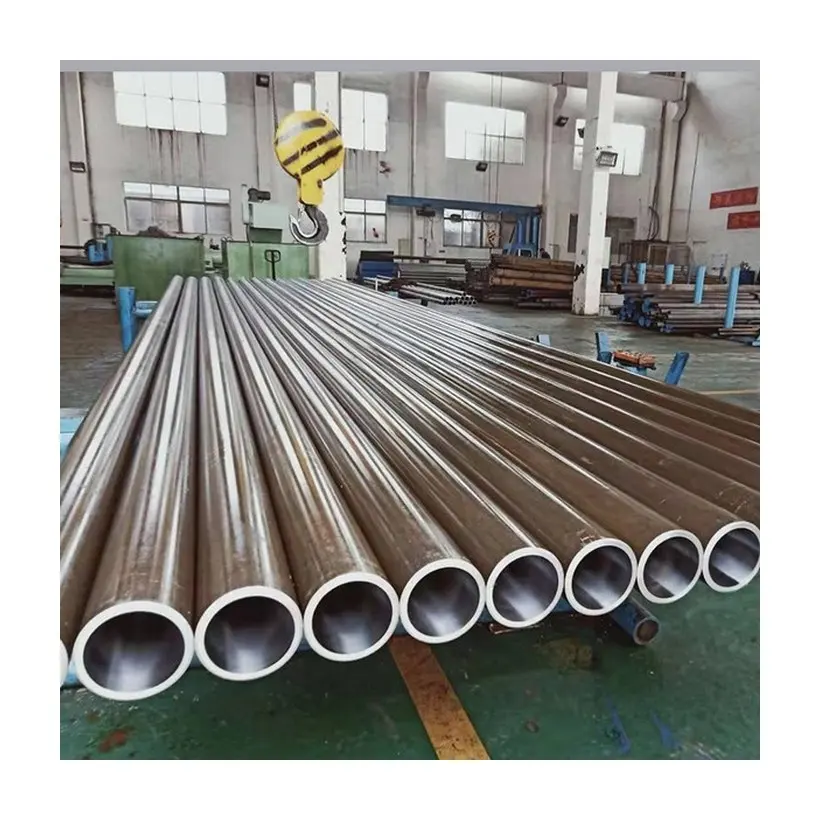

- Tšenyo ea boleng bo phahameng: Tube ea rona ea tšepe e entsoe ka tšepe ea boleng bo holimo, e netefatsa hore motho o tšoarella le ts'ebetso e telele ea ho batla.

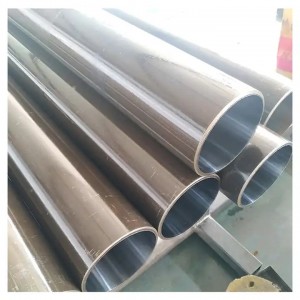

- Ho phehella ho honing: Sebaka se ka hare sa tube se fana ka ts'ebetso ea ho hula, e fella ka seipone-like seipone. Sebaka sena se boreleli se fokotsa khohlano le liaparo, li ntlafatsa tšebetso e akaretsang ea hydraulic le litsamaiso tsa Pentralic.

- Boholo bo nepahala: Tumelo ea tšepe ea tšepe e etselitsoe ho mamella ka tieo, e bonts'a boholo le boholo bo hlakileng. Ho nepahala hore ho bohlokoa bakeng sa ho boloka botšepehi ba litsamaiso e sebelisoa ho eona.

- Lipehelo tsa phapanyetsano: Sehlahisoa sena se loketse likopo tse fapaneng tsa litheolelo, ho kenyelletsa li-cylinders tsa hydraulic, li-cylins tsa li-decramatic tse fapaneng moo ho tšepahalang ho hlokahalang.

- Khatiso ea Corrosand: Tšepo e sebelisitsoeng ka har'a tube ha e loane, e etsa hore e be e loketseng ho sebelisoa libakeng tse ka tlung le tsa kantle.

- Likhetho tse nang le mokhoa o ikhethileng: Re fana ka boholo bo boholo, bolelele le bokaholimo bo senyane ho fihlela litlhoko tsa hau tse khethehileng. Likhetho tsa tloaelo li fumaneha ka kopo.

- Ho kenngoa habonolo: tube ea tšepe ea tšepe e etselitsoe ho kenya habonolo le ho kenella ts'ebetsong ka lits'ebetso tse seng li ntse li le teng, li fokotsa nako ea ho khutlisa nako kapa tlhokomelo.

Ngola molaetsa oa hau mona 'me u e romelle ho rona